Machining

TERA TECHNOLOGY Co., Ltd.

| Equipment | Model | Manufacturer | Travel distance(X-Y-Z) | Feed Drive System | Unit |

|---|---|---|---|---|---|

| Vertical Machining Center | VM1530 | Doosan Machine Tools | 3000-1500-950 | 3-Axis | 1 |

| Vertical Machining Center | MYNX 750/50 | Doosan Machine Tools | 1800-750-800 | 3-Axis | 1 |

| Vertical Machining Center | MYNX 650/50 | Doosan Machine Tools | 1300-650-625 | 3-Axis | 1 |

| Vertical Machining Center | DNM 6700 | Doosan Machine Tools | 1300-670-625 | 3-Axis | 3 |

| Vertical Machining Center | MYNX 6500/50 | Doosan Machine Tools | 1270-670-625 | 3-Axis | 1 |

| Vertical Machining Center | DNM 5700 | Doosan Machine Tools | 1050-570-510 | 3-Axis | 2 |

| Vertical Machining Center | MYNX 500 | Doosan Machine Tools | 1000-510-605 | 3-Axis | 1 |

| Vertical Machining Center | NX 5500 II | Doosan Machine Tools | 900-550-500 | 3-Axis | 2 |

| Vertical Machining Center | LCA 50A | SMEC | 800-520-520 | 3-Axis | 2 |

| Vertical Machining Center | DNM 400 | Doosan Machine Tools | 635-435-510 | 3-Axis | 1 |

| Vertical Machining Center | AF-1000 | SMEC | 800-520-520 | 3-Axis | 1 |

| Horizontal Machining Center | HM 630 | SMEC | 1000-800-800 | 4-Axis | 1 |

| Equipment | Model | Manufacturer | Max. machining diameter(Ø) | Max. machining length(L) | Unit |

|---|---|---|---|---|---|

| Horizontal Turning Center | PUMA GT 2600 | Doosan Machine Tools | Ø460 | 658L | 1 |

| Horizontal Turning Center | PUMA 280 | Doosan Machine Tools | Ø420 | 658L | 1 |

| Horizontal Turning Center | PUMA GT 2100 | Doosan Machine Tools | Ø390 | 562L | 1 |

| Horizontal Turning Center | PL-25A | SMEC | Ø380 | 530L | 1 |

| Horizontal Turning Center | PL-10 | SMEC | Ø300 | 320L | 1 |

| Equipment | Model | Manufacturer | Travel distance(X-Y-Z) | Max. rotation speed(RPM) | Oscillation(kHz) | Unit |

|---|---|---|---|---|---|---|

| ULTRASONIC MCT(ULTRASONIC MCT) | JUS41-050A | ORIIMEC(Japan) | 400-300-280 | 15,000 RPM | 40kHz | 1 |

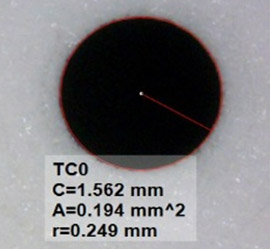

| Applied MATERIAL | AL2O3 / Y2O3 / ALN / SIC / Other difficult-to-cut materials | |||

|---|---|---|---|---|

| Technology | Ø0.1(Min. diameter)~Ø6(Max. diameter) | |||

| Strength | Fast working speed(15,000RPM) and clean machining surface to minimize arcing issues caused by particles | |||

| Machining example |  |

|

|

|

| Equipment | Model | Manufacturer | Travel distance(X-Y-Z) | Feed Drive System | Unit |

|---|---|---|---|---|---|

| Contact type 3D measuring machine | APEX V 7106 | Mitutoyo | 700-1000-600 | 3-Axis | 1 |

| Contact type 3D measuring machine | APEX V 574 | Mitutoyo | 500-700-400 | 3-Axis | 1 |

| ESC function test equipment | |

|---|---|

|

|

Manufacturer |

Custom order |

Functions |

1. Sic Wafer Chucking & De-Chucking inspection 2. He Flow & Leak inspection 3. Withstand voltage and temperature uniformity inspection |

| He Leak Detecter | |

|---|---|

|

|

Manufacturer |

ULVAC |

Model |

Heliot 700 |

Sensivity |

0.1 x 10^-13 Pa.m/s^3 |

| Surface roughness meter | |

|---|---|

|

|

Manufacturer |

Mitutoyo |

Measuring range |

0~350um |

Evaluation range |

12.5mm |

Detector's measuring power |

0.75mN |

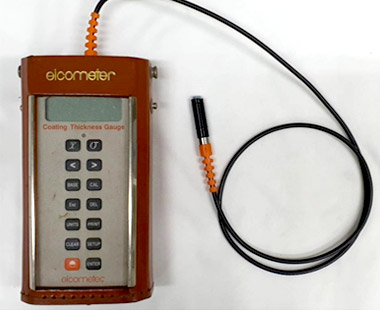

| Coating thickness meter | |

|---|---|

|

|

Manufacturer |

DeFelsko / USA |

Measuring range |

0~1500um(Fe) / 0~1500um(NFe) |

Measuring unit |

0.1um |

Accuracy |

±1um |

| Film thickness meter | |

|---|---|

|

|

Manufacturer |

Elcometer |

Measuring range |

0~250um |

Measuring unit |

0.1um |

Accuracy |

±1um |

Preparing raw materials that meet product specifications

Brazing & Welding (E-Beam)

Shape machining before joining

Brazing & Welding (E-Beam) according to production specifications

Check for abnormality on the finished product (joint leak inspection & ultrasonic inspection)

Shape machining before surface treatment (Anodizing)

Surface treatment(Anodizing) in accordance with production specifications

Shape machining according to the manufacturing specifications

Final check for abnormalities on the finished product

- Dimension inspection

- Visual inspection

- Functional test

Check product status before repair

Remove the polyimide film attached to the AL body and check the condition (determining whether repair is possible)

Flaking the surface-treated part

Flatness & Parallelism and surface roughness (Ra) management by machining the peeled part

Surface treatment(Anodizing) on AL body

Attach the film to the AL body

Final check for abnormalities on the finished product

- Dimension inspection

- Visual inspection

- Functional test

Machining technology for core components for semiconductor processing

that require high precision(Electrostatic Chuck (ESC), Showerhead, Chamber, Heater)

- Ultra-precision fine hole machining technology using drilling and ultrasonic

- Machining of various difficult-to-cut materials such as AL2O3, ALN, and SIC

- Aluminum

- Steel materials such as SUS and S45C

- Other difficult-to-cut materials

- 4M management

- Process standardization management

- Change point management

- Manufacturing process know-how