Anodizing

AMICUS CO., LTD.

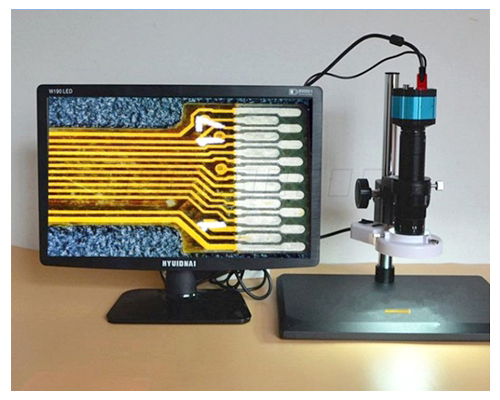

Check product status before anodizing

Taping using special film

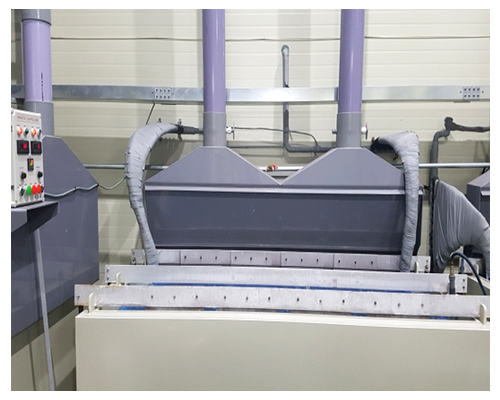

Removing contaminants from the product surface

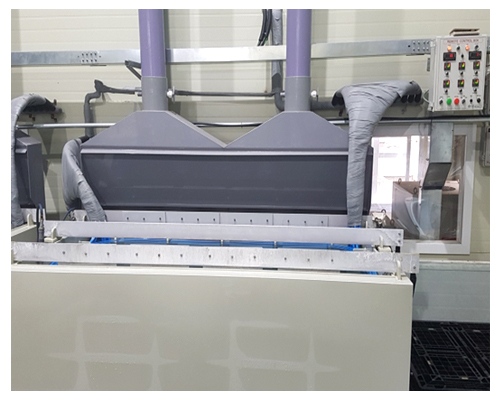

Forming an insulating layer on the surface of the product

Removing contaminants from the anodizing surface

Improving corrosion resistance and abrasion resistance by forming a thin coating film on the anodizing surface

Drying the product at the room temperature or in an oven for a certain period of time

Final check for abnormalities on the finished product

- Anodizing Thickness

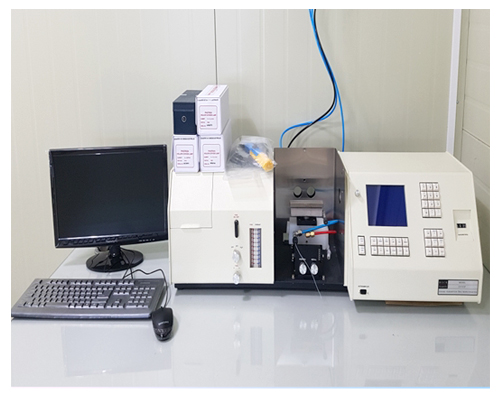

- Surface roughness (Ra)

- Exterior

Check product status before Bead Blast

Taping using special film

Surface treatment using abrasives

Drying the product at the room temperature or in an oven for a certain period of time

Final check for abnormalities on the finished product

- Surface roughness (Ra)

- Exterior

- Hard Anodizing

- Soft Anodizing

- Oxalic Acid Anodizing

- Anodizing regeneration technology for expired ESCs and chambers

- Partial anodizing regeneration technology for damaged anodizing parts

- Process technology for electro polishing

- ESD (Electro Static Discharge) process technology

- Bead Blast process technology

To form an oxide film(AL2O3) on the surface of aluminum(AL) products to prevent oxidation and increase durability

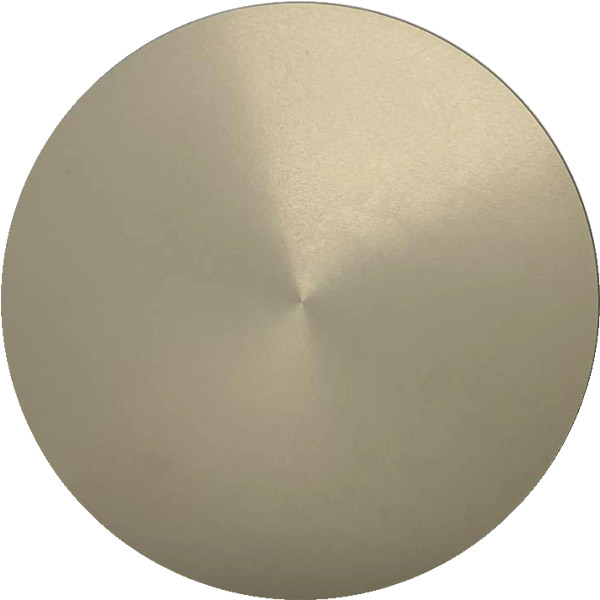

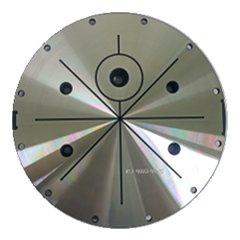

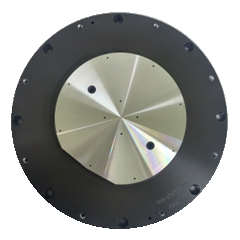

| 종류 | Hard Anodizing |

Soft Anodizing |

Oxalic Anodizing |

|---|---|---|---|

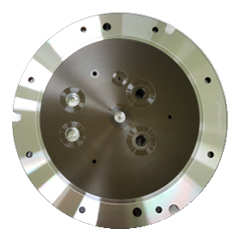

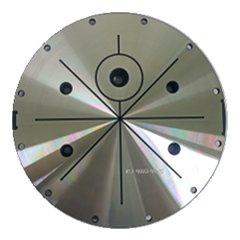

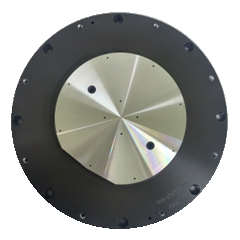

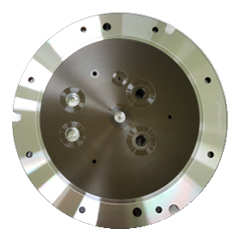

| 이미지 |  |

|

|

| Description | A surface treatment method used to improve functional properties such as hardness, corrosion resistance, abrasion resistance, and electrical insulation of the aluminum surface | Coating method for protection and decoration of aluminum It is a surface treatment method widely used for product advancement due to its excellent decorative properties as it can be color treated with various dyes after film treatment. | Anodizing method mainly used in Japan For high-purity AL, the film with the best hardness and corrosion resistance can be obtained. |

| Features | 1. Thick coating layer(Al2O3) 2. Functional properties(hardness, corrosion resistance, abrasion resistance, etc.) are significantly improved. |

1. Thin coating layer(Al2O3) 2. Excellent corrosion prevention and insulation effect. |

1. The best mechanical strength such as the best hardness and corrosion resistance can be obtained. 2. High-strength film and gloss can be obtained even with low-purity AL. 3. Maintenance cost is high. |

| Film thickness(㎛)) | 25~120㎛ | 10~25㎛ | 10~100㎛ |

| Surface hardness(Hv) | 250~260Hv(Based on 50㎛) | 150~270Hv(Based on 20㎛) | 300~800Hv(Based on 50㎛) |

| Corrosion resistance (salt spray test) | Over 8,600 hr.(Based on 50㎛) | Over 5,000 hr. (Based on 20㎛) | Over 10,000 hr. (Based on 50㎛) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|